|

Best viewed using

buy, Philip

phone, card, cards,

phonecard, phonecards, sell, sale, sales, cheapest, call, free, hello, asia,

disabled, wheelchair, help, hearing, deaf, Villahermosa, Cebu, Talisay, Lawa-an,

Philippines, Tabunok, support, impaired, Michael, Lorena, St., Saint, Louis,

Missouri, charity, non, for, profit, Filipna, Filipno, deaf, school, philippine,

schools, children, kid, kids, adults, schooling, supplies, philippine deaf,

philippine school, deaf school, donate, used, hearing, aid, aids, fund, loss,

donation, donations, Filipino, PI, Cebu, help, children, kids, impaired,

disabled, hear, sign language, PI, disability, help, helping, community,

impaired, give

| |

|

[ John-John ] [ Hearing Loss ] [

Tour Cebu, PI ]

[ Types of Loss ] [ 4

basic types ] [ How they Work ] [ 10 Myths ] [

Glossary ]

The 4 basic types of hearing aids...

There are four basic types of hearing aids common to most manufacturers. All

four will help with mild to moderate losses, but if loss is more severe, choices

can be more limited. While size is the most obvious difference, each style has

different attributes that are important to consider.

Hearing aids worn behind-the-ear or in-the-ear can carry more sophisticated

technology and more powerful amplifiers; they are also more durable. In

contrast, new smaller models reside closer to the eardrum, and that proximity to

the inner ear can help deliver a more natural sound quality. Your hearing

professional will provide you with a recommendation and rationale thatís based

on your specific needs and physiology.

|

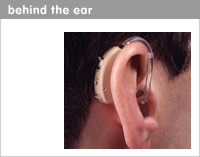

Behind-the-ear (BTE) aids have a plastic housing for the components which rests behind

the ear. A clear plastic tube funnels amplified sound into an earmold in

the ear canal. This model, though developed decades ago, can be every

bit as sophisticated as smaller hearing aids. In fact, it can hold more

circuitry and amplify sounds to a greater degree than in-the-ear types.

BTE aids can be more durable than other types and a few are even

waterproof.

|

|

|

|

|

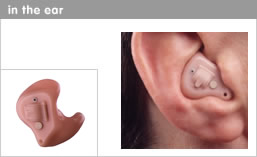

In-the-ear (ITE) aids house componentry in a custom-formed earmold that fits within

the outer portion of the ear. Its size and easy-to-use controls also may

be helpful for those with limited manual dexterity.

|

|

|

|

|

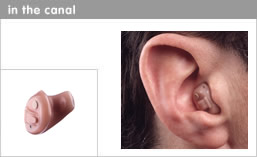

In-the-canal

(ITC) aids are smaller still, with an earmold that fits down into the

ear canal, and a smaller portion facing out into the outer ear. They are

discreet, yet still visible within the outer ear.

|

|

|

|

|

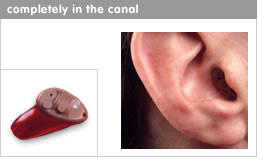

The

newest generation of hearing aids are those that fit completely in the

canal (CIC). Barely visibleóand then only if someoneís peering into

your earóthe only clue to their existence is the head of a tiny

plastic line with which you place or remove the aid. CICs are popular

for their aesthetic appeal, but the physiology of some individualsí

ears (i.e., a very narrow canal) may make this style unsuitable for

them.

|

|

|

|

|

|

New technologies

Hearing aid technology has come a long way in the last few years,

thanks to the computer microchip and digital circuitry. Here are some of

the latest innovations.

Digital technology

Why does music from a cd sound more crisp, clear, and distortion-free

than music from a record or tape? The answer, at least in part, is the

difference between analog and digital sound processing.

Digital hearing aids have one or more microchip processors inside them

that convert analog sound waves into the zeros and ones of computer

language. Sound in this format can be processed more quickly and more

efficiently than analog sound waves; in fact, incoming sounds are sampled

at a rate of a million or more times per second. The digital aidís

circuitry analyzes these sound levels and frequencies, manipulating them

to provide a more efficient match to an individualís hearing profile.

For example, a person with hearing loss may have trouble hearing soft

sounds, but when some sounds are amplified even a small amount, they

become uncomfortably loud. Hearing aids with digital compression circuitry

are able to stratify incoming sounds, detect those that need amplification

from those that donít, and process the sound accordingly.

Programmable technology

Digitally programmable hearing aids, which are different from fully

digital aids in that theyíre not equipped to process all incoming sound

digitally, offer the very useful benefit of being able to sculpt sound to

fit a particular individualís unique hearing profile, and can be

reprogrammed if there are changes in hearing loss. Programmable aids can

be set up with multiple channels, enabling you to preset and store several

different programs, each sculpted to a particular set of sound

environments. You can then select the appropriate program using a button

or remote control unit: normal conversation, concert hall, office, or

telephone, for example.

Feedback reduction technology

Feedback has long been a problem for hearing aid wearers. Now we know

a lot more about feedback, and have developed ways to deal with it.

Feedback happens when amplified sound waves escape back out through the

ear canal and are then re-amplified by the hearing aidóresulting in the

high-pitched squeals that set your teeth on edge. Smaller, in-the-canal

styles of hearing aids place components closer to the eardrum, preventing

sound waves from escaping, thereby reducing, and often eliminating,

feedback. Some new aids are also able to detect these sounds before they

become audible and cancel them out, greatly reducing this frustrating

problem.

How hearing aids are made

Hearing aids are not a standardized product; each aid has elements,

including the shell or earmold, that are custom-made for the wearer. If

you decide to try a hearing aid, the steps are quite simple. After the

testing process, your hearing professional will make an impression of your

ear, a relatively easy process.

A bit of cotton or foam is placed well into the ear canal to block any

of the impression material from reaching the eardrum. Then the malleable

impression material is placed in the ear until it sets, which takes a few

minutes. Once it has conformed to the shape of your ear, itís gently

removed.

This impression or mold of your ear is sent, along with your audiogram

and other test results, to the manufacturerís lab. Hearing aids are

individually constructed, beginning with the plastic housing or earmold,

an exact replica of your ear impression. Circuitry is added, the aid is

tested, and then shipped back to your hearing professional.

When the finished hearing aid is sent back, youíll see your hearing

professional for the fitting. This is likely to include repeating some of

the audio testing you underwent initially, as well as tests that measure

the hearing aidís performance. As your hearing aid is fine-tuned, itís

a good time to ask questions, and talk through initial expectations with

your hearing professional. You may need to come back a time or two for

further adjusting, which is typical and usually covered in the purchase

price of most hearing aids.

Provided by Starkey Labs

|

|

|